How we make it

Co.Ro. is team-play. A crew of goldsmiths, engravers and smelters turns the visions of the two creative directors into living matter.

The outcome is the result of ancient and experimental techniques mixing together: from the

blank sheet to the living matter of the final piece.

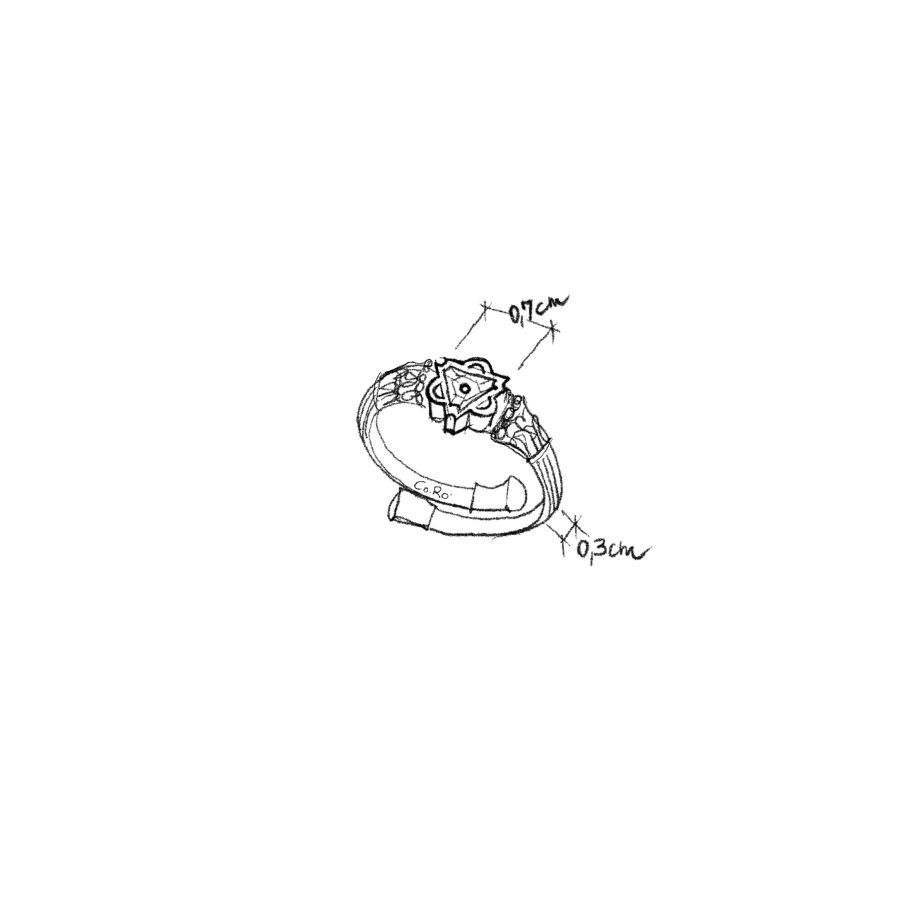

A laborious project phase

Each piece of jewellery is an architectural composition: the initial idea goes under a laborious project phase, made of

trials and sketches, of bidimensional practice with pencil

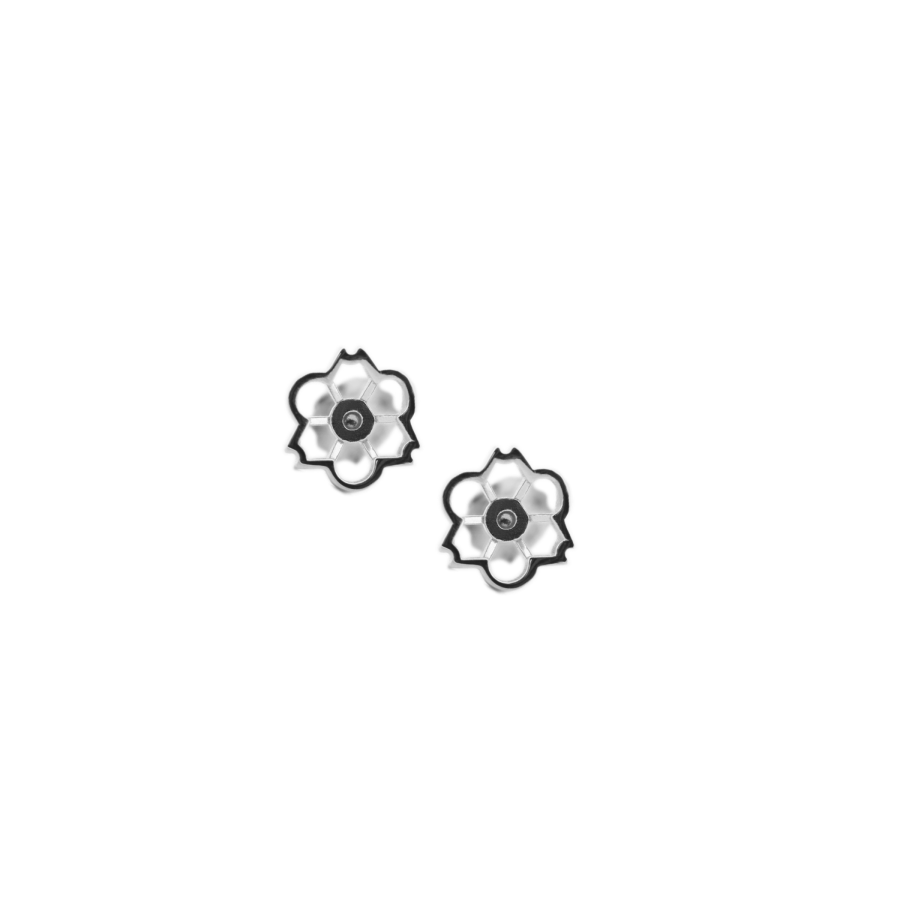

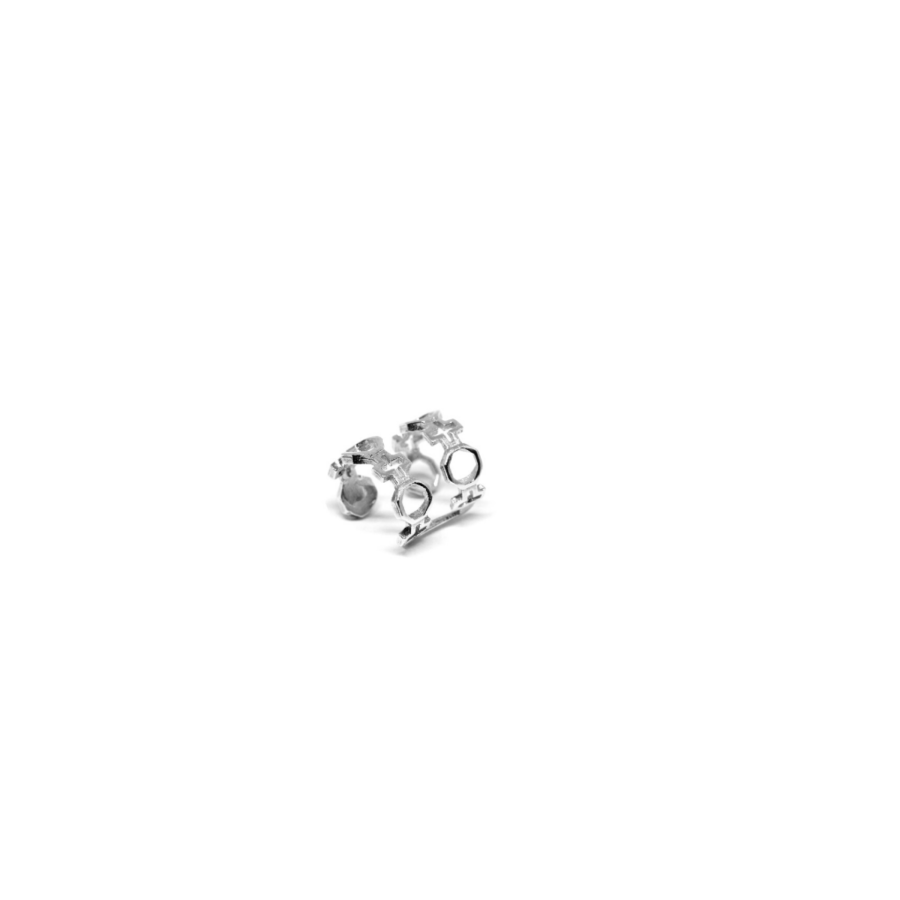

Wax micro-sculptures

and 3D implementation of wax micro-sculptures through

digital printing and handshaping.

Casting

The wax models are assembled together and immersed in plaster, here a jet of molten silver at high pressure will take the place of the wax, which is precisely called “lost”

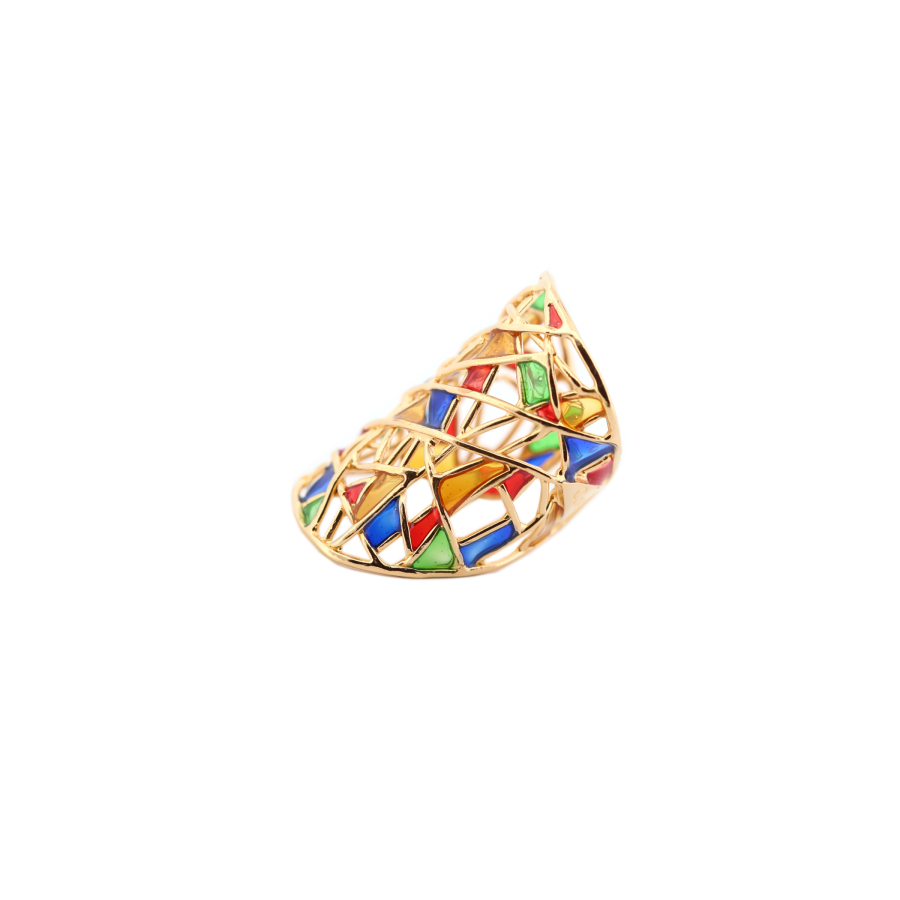

polishing and finishing

The castings are carefully filed and finished by skilled craftsmen to obtain the final geometry and surface finish.

And the magic happened!